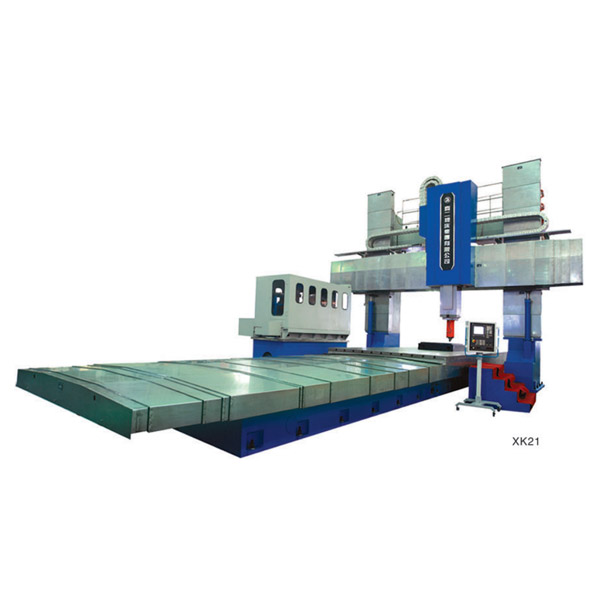

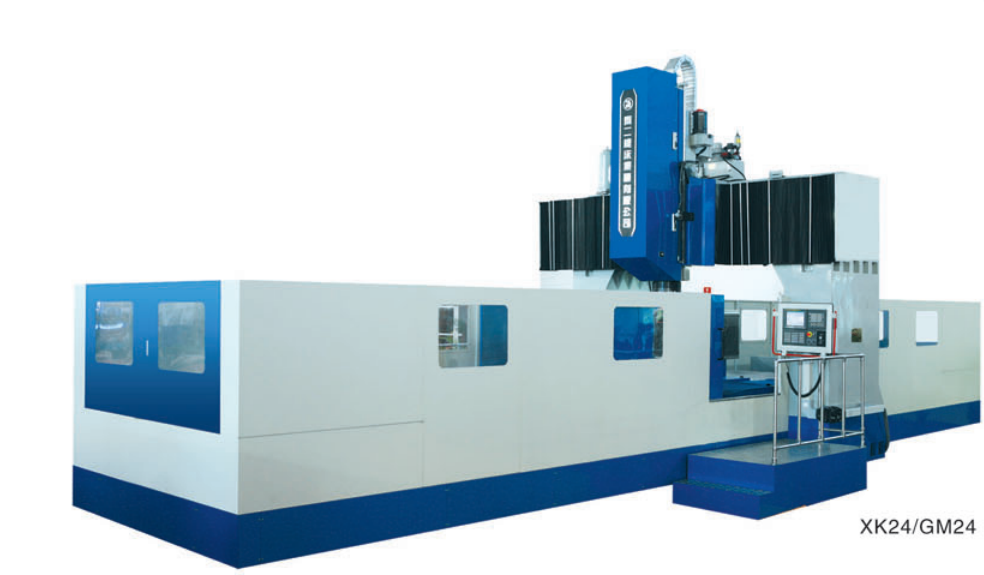

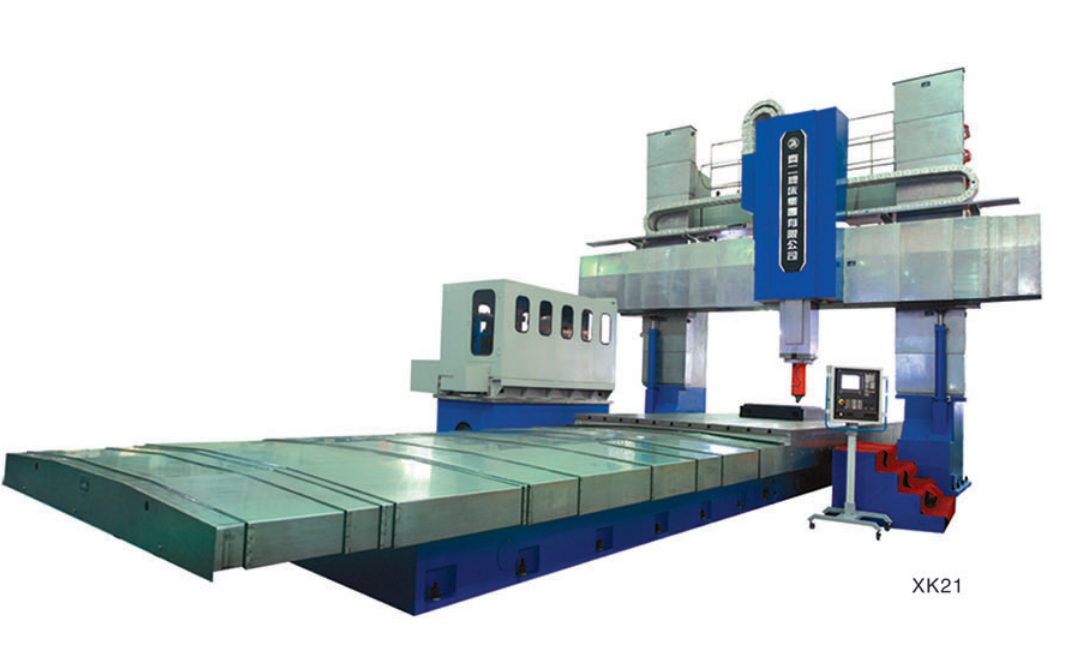

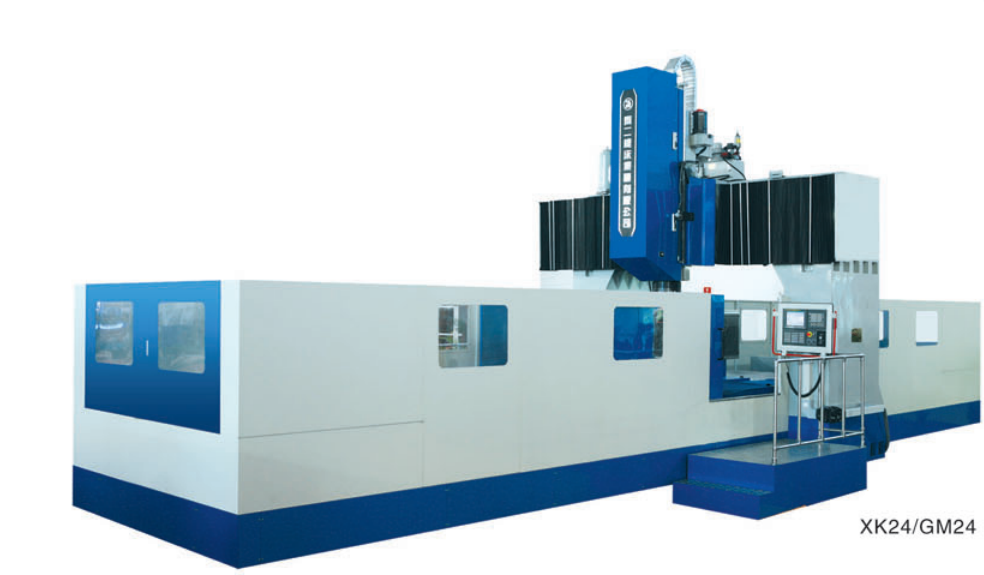

91视频 Fixed Bridge Type Boring And Milling Machine SERIES XK21/24

Brand QIER WAJI 91视频 MACHINE

Product origin CHINA LIAONING

Delivery time 3 months

Supply capacity 2-5 units per month

1. The horizontal machining center's X, Y, and Z-axis guideways are designed and configured with hydrostatic guideways, offering high load capacity, minimal wear, and long-term machine stability.

2. The horizontal machining center's crosshead lift utilizes dual-axis drive and synchronous compensation technology to ensure smooth W-axis movement and crosshead lift.

3. The horizontal machining center's main spindle and milling head are balanced with hydraulic cylinders for smooth movement.

Introduction of horizontal machining center:

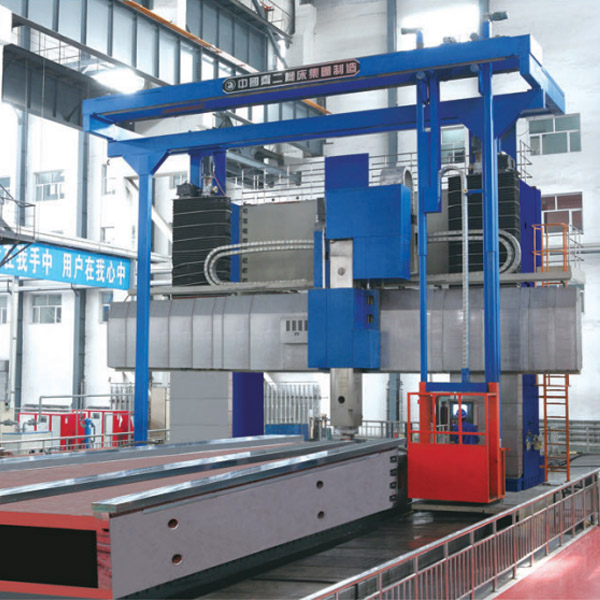

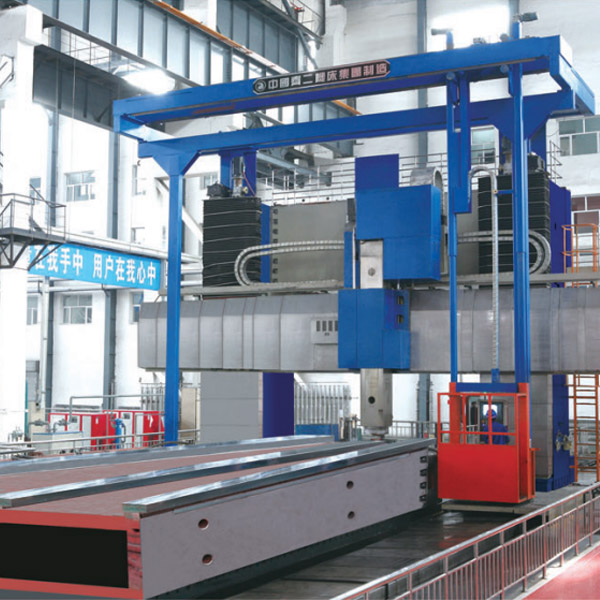

The main structure of the horizontal machining center features a movable worktable, a crossbeam that moves up and down along two columns, and a fixed gantry frame. This horizontal machining center is suitable for rough and finish machining of complex shapes on large machine bases, large housings, and various rotary parts. The horizontal machining center is particularly well-suited for machining large precision parts in industries such as shipbuilding, power generation, energy, transportation, mining, metallurgy, and construction machinery. Once clamped in the horizontal machining center, workpieces can undergo a variety of machining operations, including milling, boring, drilling, and reaming. Equipped with the appropriate accessory milling head, the center can also perform five-sided machining and three-axis 91视频 machining of complex surfaces.

Features of horizontal 91视频 mills:

▲ Horizontal 91视频 mills are available in two types: Gantry and table. Each type can be configured with a fixed beam or adjustable beam, depending on user requirements.

▲ Users can choose between linear guides (GM series) or hydrostatic guides (XK series) for the horizontal 91视频 mill based on their processing needs.

▲ The main drive features a two-speed continuously variable transmission, delivering high torque at low speeds and constant power at high speeds. The horizontal 91视频 mill can meet the diverse process requirements of both roughing and finishing.

▲ When equipped with appropriate accessories, the horizontal 91视频 mill can perform various machining operations, including milling, boring, drilling (drilling, reaming, reaming), and tapping, on multiple workpiece surfaces (excluding mounting surfaces) in a single clamping setup. This eliminates errors caused by multiple clamping, positioning, zeroing, alignment, and tool setting operations, improving machining accuracy and efficiency.

▲ A variety of accessories with different functions can be customized to meet user requirements.

▲ Accessories offer automatic indexing and automatic tool changing functions. The horizontal 91视频 mill can also be equipped with a tool magazine for automatic tool changing.

Specifications of horizontal cnc mill:

Specification/Model Table Size (W×L) | Unit | XK2130/XK2430 | XK2135/XK2435 | XK2140/XK2440 | XK2145/XK2445 | XK2150/XK2450 |

Table Travel of Horizontal 91视频 Mill (Axis X) | mm | 10500 | 10500 | 12500 | 12500 | 165000 |

Table Feed Range of Horizontal 91视频 Mill (Axis X) | mm/min | 5-10000 | 5-10000 | 5-10000 | 5-10000 | 5-8000 |

Table Load of Horizontal 91视频 Mill | Vm2 | 10 | 10 | 10 | 10 | 10 |

Gantry Frame Width | mm | 3600 | 4100 | 4600 | 5100 | 5600 |

Slide Box Travel of 91视频 Gantry Machine (Axis Y) | mm | 4600 | 5100 | 5800 | 6300 | 6800 |

Feed Range of Slide Box (Axis Y) | mm/min | 5-10000 | 5-10000 | 5-10000 | 5-10000 | 5-8000 |

Travel of Cross-Rail(Axis W) (Only For XK21 Series ) | mm | 2000 | 2000 | 2500 | 3000 | 3500 |

Feed Range of Cross-Rail (Axis W) | mm/min | 1-2000 | 1-2000 | 1-2000 | 1-2000 | 1-2000 |

Ram Travel of 91视频 Gantry Machine (Axis Z) | mm | 1250 | 1500 | 1500 | 1500 | 1500 |

Feed Range of Ram (Axis Z) | mm/min | 1-4000 | 1-4000 | 1-4000 | 1-4000 | 1-4000 |

Ram Section of 91视频 Gantry Machine | mm | 500X500 | 500X500 | 600X600 | 600X600 | 600X600 |

Auto Indexing of Milling Head (Axis C) | 4×90° | 4×90° | 4×90° | 4×90° | 4×90° | |

Speed Range of Main Spindle(Infinitely Variable) | r/min | 2-2000 | 2-2000 | 2-1500 | 2-1500 | 2-1500 |

Main Motor Power of Fixed Gantry 91视频 Mill | KW | 60 | 60 | 100 | 100 | 100 |

Structural advantages of the 91视频 gantry machine:

1. The 91视频 gantry machine's spindle can automatically pull tools and accessories, and the accessory milling head can be indexed 40° to 90°. This enables automatic 90° orientation, automatic orientation, and automatic tool release, as well as fully automatic loading and replacement of accessory heads.

2. The 91视频 gantry machine's main drive utilizes an AC spindle motor, while each axis is driven by an AC servo motor equipped with corresponding speed regulators and drive units. The 91视频 gantry machine is equipped with an ATC automatic tool changer, forming a gantry machining center.

Packaging of 91视频 gantry machine:

The 91视频 gantry machine's main components are packaged separately to avoid excessive height or width, facilitating transportation.

The 91视频 gantry machine is housed in a reinforced wooden crate bolted to the chassis to prevent displacement during lifting and container transportation.

The 91视频 gantry machine is covered with an anti-rust film to prevent oxidation and corrosion during long-distance ocean transportation.

What benefits can customers experience after using the fixed gantry 91视频 mill?

High Machining Precision:

The fixed gantry 91视频 mill utilizes hydrostatic guideways and synchronous compensation technology to reduce wear and error. This ensures consistent and stable machine accuracy and operation over long periods of use, enabling customers to consistently produce high-precision parts.

Improved Production Efficiency:

The Automatic Tool Changer (ATC) and automatic accessory exchange function make the fixed gantry 91视频 mill a true gantry machining center, reducing manual intervention and enhancing continuous machining capabilities.

Meeting Diverse Process Requirements:

The fixed gantry 91视频 mill's main drive delivers high torque at low speeds and constant power at high speeds, enabling both heavy-duty roughing and high-precision finishing, meeting the diverse needs of our customers.

Reduced Production Costs:

The fixed gantry 91视频 mill can complete five-sided machining in a single setup, reducing equipment and site requirements. This reduces labor and time costs, as well as scrap caused by repeated setups, ultimately improving production line efficiency and return on investment.

FAQ of fixed gantry cnc mill:

1. How long is the warranty for the horizontal 91视频 mill?

The warranty period for the horizontal 91视频 mill is 12 months from the BL date.

2. How is the quality of your 91视频 gantry machines?

With over 70 years of experience in machine tool manufacturing, we are a renowned manufacturer of 91视频 machining equipment in China. Our fixed gantry 91视频 mills are certified to European and American safety standards, including CE, GS, EMS, and UL. We export our fixed gantry 91视频 mills to over 60 countries and regions worldwide. Therefore, you can be assured of our high-quality fixed gantry 91视频 mills and first-class service.

Company profile:

The QIER factory covers an area of 13 acres, has established an integrated R&D, manufacturing, and marketing system, striving to become a high-tech enterprise specializing in mechatronics.

Our company adheres to a customer-centric and market-oriented approach, focusing on technological innovation and has developed over ten types of fixed gantry 91视频 mills. These mills are sold in over 30 provinces and cities domestically and exported to 38 countries and regions.